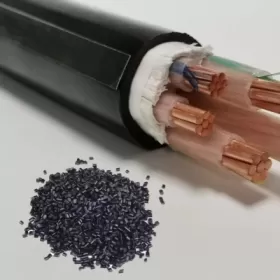

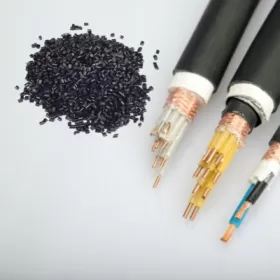

Low Smoke Zero Halogen LSZH materials are high-performance flame-retardant materials composed of polyolefin blend resins mixed with flame-retardant hydroxide fillers, and they do not contain halogen elements. LSZH materials produce minimal smoke when burned and are free from halogens, making them safer in fire situations by reducing the generation of toxic smoke, thereby enhancing escape and rescue possibilities.

·Low Smoke Zero Halogen LSZH compounds are widely used as cable sheathing materials globally.

·LSZH stands for "Low Smoke Zero Halogen" a commonly used halogen-free flame-retardant material in cable sheathing.

·LSZH materials produce little smoke, are low in toxicity, and have minimal corrosiveness, demonstrating excellent fire safety performance.

·LSZH cables are commonly used in densely populated areas such as office spaces and public transportation systems.

Since 2011, Angreen has been developing low smoke halogen-free (LSOH) materials for various applications, including B1 cables, rail transit, building decoration, and data communication, in accordance with the requirements of the CRP (Construction Products Regulation) in Europe.

Angreen's low smoke halogen-free materials support cable compliance with CPR EN50575 classifications (B2ca, Cca, Dca, Eca) for burning tests.

LSZH sheath materials feature higher flame-retardant ratings and drop test ratings, exhibiting excellent processing characteristics and quality even under high flame-retardant performance.

Angreen's high-voltage Low Smoke Zero Halogen cable material solutions fully meet the low-friction LSZH requirements for temperature resistance and flame retardancy in high-voltage harnesses, satisfying ISO 6722 at 125℃.

B1 Class Cables: B1 flame-retardant cables for public places such as hospitals, schools, and offices.

Communication Cables and Fiber Optic Cables: Used to reduce fire risk in applications such as computers, communication equipment, and servers.

Rail Transit Cables: Used to improve passenger safety in applications such as airplanes, trains, and automobiles.

Low Smoke Halogen-Free (LSZH) compounds are widely used in cable sheaths. Cable manufacturers not only need materials that meet basic safety, flame retardancy, and mechanical performance standards, but also require greater cost-effectiveness in large-scale production.

Angreen's Low Smoke Zero Halogen Materials Fully supports fiber optic cables, power cables, and network cables in passing EN 50575 (B2ca, Cca, Dca) and GB31247 (excluding A) fire tests (different product names meet different fire test levels).

We offer professional LSZH sheath material solutions designed for various application scenarios, with primary product offerings including:

·High Flame Retardancy LSZH: Compliant with EU CPR regulations and China GB31247;

·High Hardness LSZH: Hardness ≥65D or ≥98A; supports a wide operating temperature range of -40℃ to 125℃;

·Low Friction LSZH: Low friction coefficient for easy on-site handling;

·High-Temperature Resistant LSZH: Non-stick at 125℃ for 1000 hours;

·High-Temperature Anti-Shrinkage LSZH: High-temperature cyclic shrinkage ≤5‰ at 85℃; low-temperature cyclic shrinkage ≤5‰ at -40℃;

·High-Low Temperature Shrinkage LSZH: High-low temperature cyclic shrinkage ≤5‰ between -40℃ and 85℃; supports long-term use in a wide temperature range of -40℃ to 125℃.

·Silane Crosslinking LSZH:The Flame retardant grade pass IEC60332 Single vertical cable combustion test and Bunched cables combustion test.

·Irradiation cross-linking LSZH:Using UV irradiation LSZH, it is suitable for large-scale and efficient mass production of thin-wall insulation layers of wires and cables. The flame retardant grade has passed the IEC60332 single cable vertical combustion test and bundled cable combustion test.