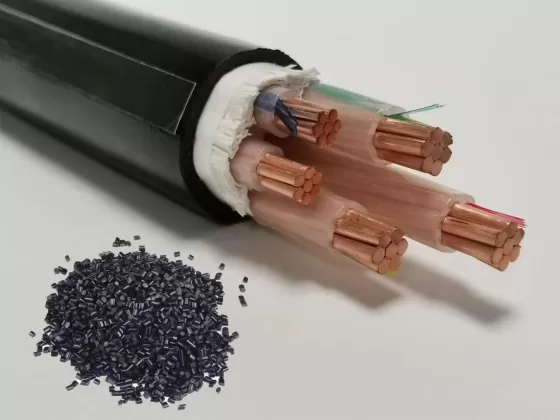

B2 grade insulation material is made of high purity resin as base material, with halogen-free flame retardant, antioxidant, etc. mixed and extruded into granules. It has excellent performance such as halogen-free, heat-resistant, and weather-resistant, has no precipitation pollution, meets the relevant requirements of Rohs, and is easy to extrude and process.

Application: Related cables of GB/T 31247 standard

| Testing items | VALUE | Typicalvalue | UNIT | Method |

| Density | ≤1.65 | 1.62 | g/cm3 | GB/T1033 |

| Low-temperature brittle temperature | ≤15/30 | 0/30 | 个 | GB/T5470 |

| Environmental stress cracking resistance | ≥96 | 108 | F0/h | GB/T2951 |

| Thermal stress cracking resistance | Uncracked | Uncracked | 一 | GB/T32129 |

| Tensile strength before aging | ≥10 | 11.8 | MPa | GB/T2951 |

| Elongation at break before aging | ≥150 | 180 | % | GB/T2951 |

| Performance after aging110℃×168h | ||||

| Change rate of tensile strength | ≤±30 | 10 | % | GB/T2951 |

| Change rate of elongation at break | ≤±30 | -9 | % | GB/T2951 |

| Volume resistivity at 20℃ | ≥1.0×1012 | 5.6×1012 | Q.m | GB/T1410 |

| Dielectric strength | ≥18 | 20 | MV/m | DIN EN 6024 |

| Oxygen index | ≥35 | 37 | % | GB/T2406 |

| Smoke density flame method | ≤100 | 80 | / | GB/T8323 |

| Smoke density flameless method | ≤350 | 200 | / | GB/T8323 |

| Hydrogen halide gas content | ≤5 | 0 | m/g | GB/T17650 |

| Combustion gas pH value | ≥4.3 | 5.9 | / | GB/T17650 |

| Combustion gas conductivity | ≤10 | 6 | μs/mm | GB/T17650 |

| Water absorption test70℃×24h | ||||

| Maximum weight gain | ≤10 | 5 | mg/cm² | GB/T32129 |

| Peak heat release rate | ≤180 | 100 | kW/m2 | lS0/5660 |

| Total heat release | ≤180 | 110 | MJ/m2 | IS0/5660 |

| Average heat release rate | ≤100 | 80 | kW/m2 | 1S0/5660 |