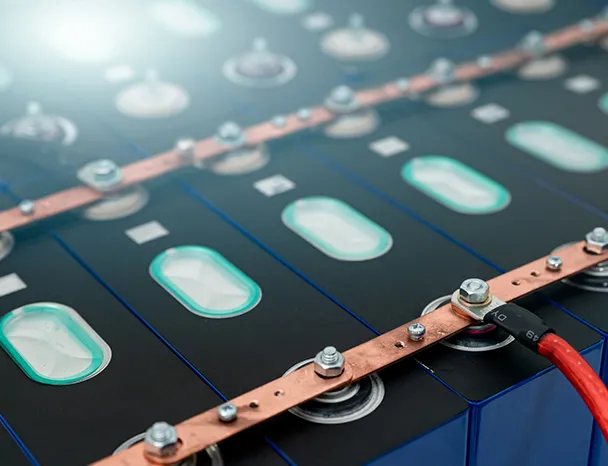

Energy storage battery connection cable materials are widely used in energy storage battery connection cables in electric vehicles, automobiles, new energy vehicles and other fields, mainly based on irradiated cross-linked polyolefin materials.

The Product Models And Product Names of Our Company Are as Follows

| Energy Storage Battery Connecting Cable Material | |

| PFXOR90560 | Irradiation cross-linked flame-retardant polyolefin cable material for 125°C energy storage cables (VW-1) |

| PFXOR85543 | Irradiation cross-linked polyolefin cable material for 125°C energy storage (large wire) |

| PFXOR85542 | Irradiation cross-linked polyolefin cable material for 125°C energy storage (small wire) |

The application areas of polyolefin materials for energy storage battery connection cables are mainly concentrated in cables used in various scenarios requiring energy storage, conversion, and dispatch, including:

Connection cables between battery modules and inverters in residential energy storage and rooftop photovoltaic systems.

Connection cables between high-current battery clusters, DC combiners, and protection devices in large-scale centralized or distributed energy storage power stations, in grid-side energy storage, peak shaving, and frequency regulation systems.

Power cables connecting photovoltaic modules, energy storage batteries, and inverter equipment in integrated photovoltaic-energy storage systems to achieve photovoltaic power generation.

Connection cables between battery stacks and PCS (converter-controlled system) in wind power grid-connected projects.

Connection cables for mobile or portable energy storage devices, including outdoor power supplies and mobile energy storage vehicles, responsible for internal connection cables between battery modules.

The selection of cable materials for energy storage battery cables is critical to ensuring the performance and safety of the battery system. These cables need to meet a range of requirements, including but not limited to high and low temperature resistance, chemical corrosion resistance, good mechanical strength, flexibility, and excellent electrical insulation properties.

The following are some cable materials and their characteristics suitable for energy storage battery cables:

XLPE Cross-linked Polyethylene: XLPE material has excellent heat resistance and chemical corrosion resistance, while providing good electrical insulation properties. It is usually used to make cables with higher temperature resistance levels, suitable for energy storage systems with long-term high-power charging and discharging.

PVC (Polyvinyl Chloride): PVC is a lower-cost cable material with good chemical resistance and certain heat resistance. But its temperature resistance level is usually lower than XLPE, suitable for cost-sensitive and less demanding applications.

Silicone Rubber : Silicone cables have excellent heat resistance and chemical resistance, especially suitable for use in high-temperature environments. They are often used in applications that require excellent heat and chemical corrosion resistance.

TPE (Thermoplastic Elastomer): TPE cable materials provide good flexibility and chemical resistance, easy installation and wiring, and are suitable for applications that require frequent movement or bending.

Copper alloy or aluminum alloy conductor: In some applications, copper alloy or aluminum alloy may be used as conductor material to reduce costs. These materials can reduce material costs while maintaining electrical performance.

The selection of energy storage battery connection cable also needs to consider factors such as the cable's rated voltage, current capacity, laying environment (indoor or outdoor), mechanical strength, flame retardant properties, and service life.When selecting cable materials for energy storage battery connection cables, relevant industry standards and specifications, such as T/CNESA 1003-2020, should be followed to ensure that the performance and safety performance of the cable meet the requirements of the energy storage system.